Engraving Printing

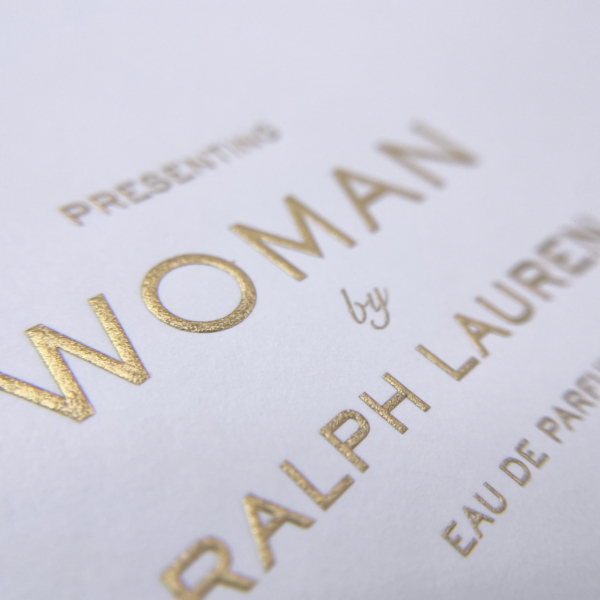

Engraving, also known as intaglio printing, lines are meticulously cut into a metal plate using a burin. This process ensures exacting precision and depth, resulting in finely detailed prints.

To begin, ink is applied to the plate’s surface and pushed into the recessed lines or grooves. Excess ink is then wiped away, leaving ink only in the etched impression of the plate, forming the intended image.

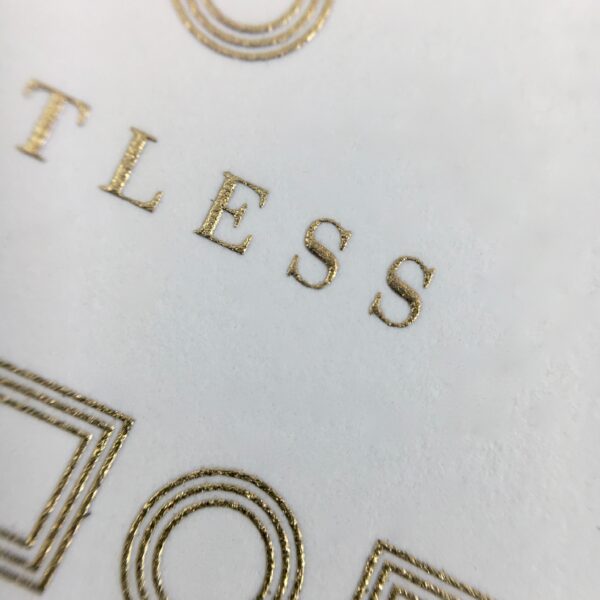

Next, a piece of paper is fed into the press and placed on top of the plate. Immense pressure is applied, squeezing the paper into the plate’s ink-filled grooves. As a result, the ink is transferred from the etched areas of the plate to the paper, creating a printed sheet with a raised ink impression.

Benefits of Engraving Printing:

Unparalleled Quality:

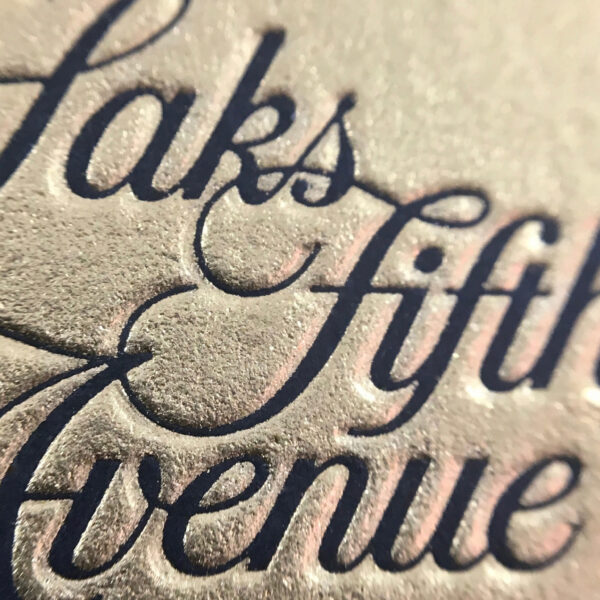

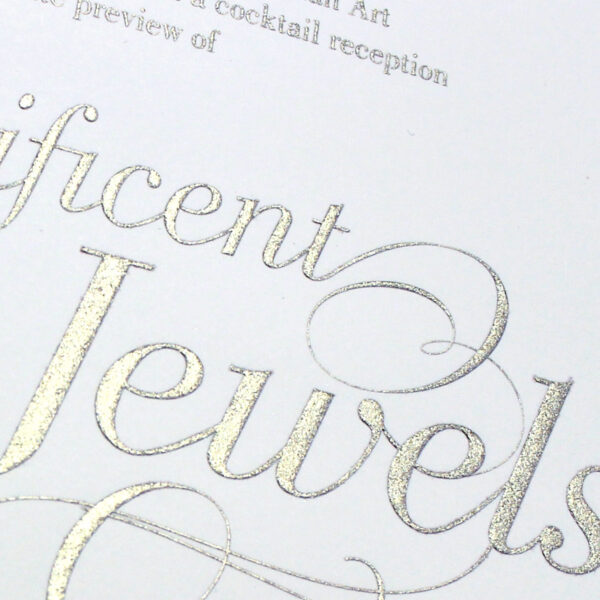

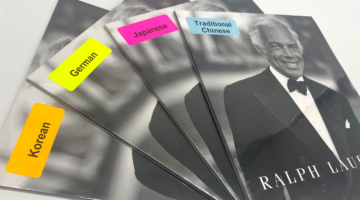

Engraving printmaking delivers unmatched quality, with precise lines and rich textures that exude luxury and sophistication. The depth and clarity of engraved designs elevate the overall aesthetic of printed materials, making them highly desirable in luxury branding and marketing.

Distinctive Elegance:

Engraving printing adds a distinctive elegance to luxury commercial printing, setting brands apart with its refined and timeless appeal. The raised ink impressions and tactile quality of engraved designs create a luxurious experience for customers, enhancing brand perception and prestige.

Enhanced Brand Image:

Utilizing engraving printmaking in luxury commercial printing reinforces a brand’s image of exclusivity, craftsmanship, and attention to detail. The meticulous process of engraving conveys a sense of quality and refinement that resonates with discerning clientele, elevating the brand’s reputation in the luxury market.

Attention to Detail:

The meticulous nature of engraving printmaking ensures attention to even the smallest details, resulting in prints of unparalleled precision and clarity. Every line and texture is meticulously crafted, reflecting a commitment to excellence and craftsmanship that resonates with luxury consumers who appreciate fine craftsmanship and attention to detail.